Track and Trace for Governments

What Is the Difference Between DataMatrix, QR Codes and Barcodes?

In today’s fast-paced world, governments, businesses and consumers alike rely on various types of machine-readable codes such as 2D DataMatrix codes and QR codes, as well as simple 1D barcodes.

But what exactly sets these codes apart, and why is DataMatrix the preferred choice for Track and Trace solutions?

In this post, we’ll break down the differences between these codes, highlight their unique features, and explain why DataMatrix codes are critical in industries that demand precise product tracking and traceability.

What Are Barcodes?

Barcodes are a form of product identification technology that was patented back in 1949 and upgraded into UPCs (Unique Product Codes) in 1974.

The technology is recognized by distinctive black and white parallel lines. These one-dimensional (1D) codes encode numeric or alphanumeric data and have been used for decades in retail and inventory management.

Key features of barcodes:

-

Linear, 1D format

-

Limited data storage capacity (usually 20-25 characters)

-

Widely used for product pricing, inventory control, and point-of-sale scanning

Understanding QR Codes

Developed for quick readability and greater data storage in 1994, QR codes (Quick Response codes) are two-dimensional (2D) matrix codes made up of black and white squares.

Highlights of QR codes:

-

Can store thousands of characters, including URLs, contact info, and more

-

Easily scanned by smartphones and dedicated scanners

-

Popular in marketing campaigns, mobile payments, and consumer engagement

DataMatrix Codes and Their Purpose

DataMatrix codes are compact 2D codes known for their high data density and excellent error correction. They were developed in 1994 as well.

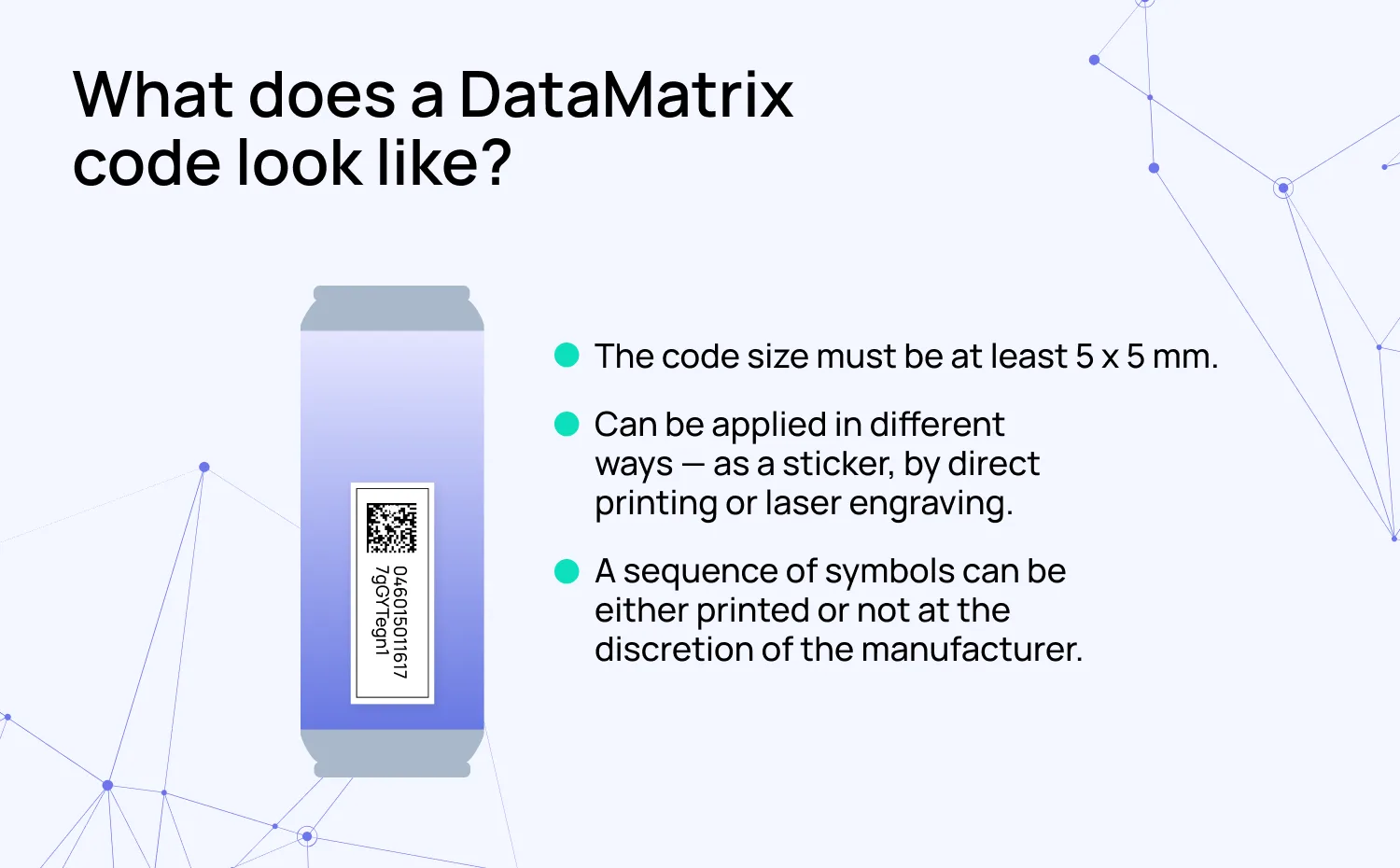

Unlike QR codes, DataMatrix codes are often smaller, making them ideal for marking tiny components or packaging.

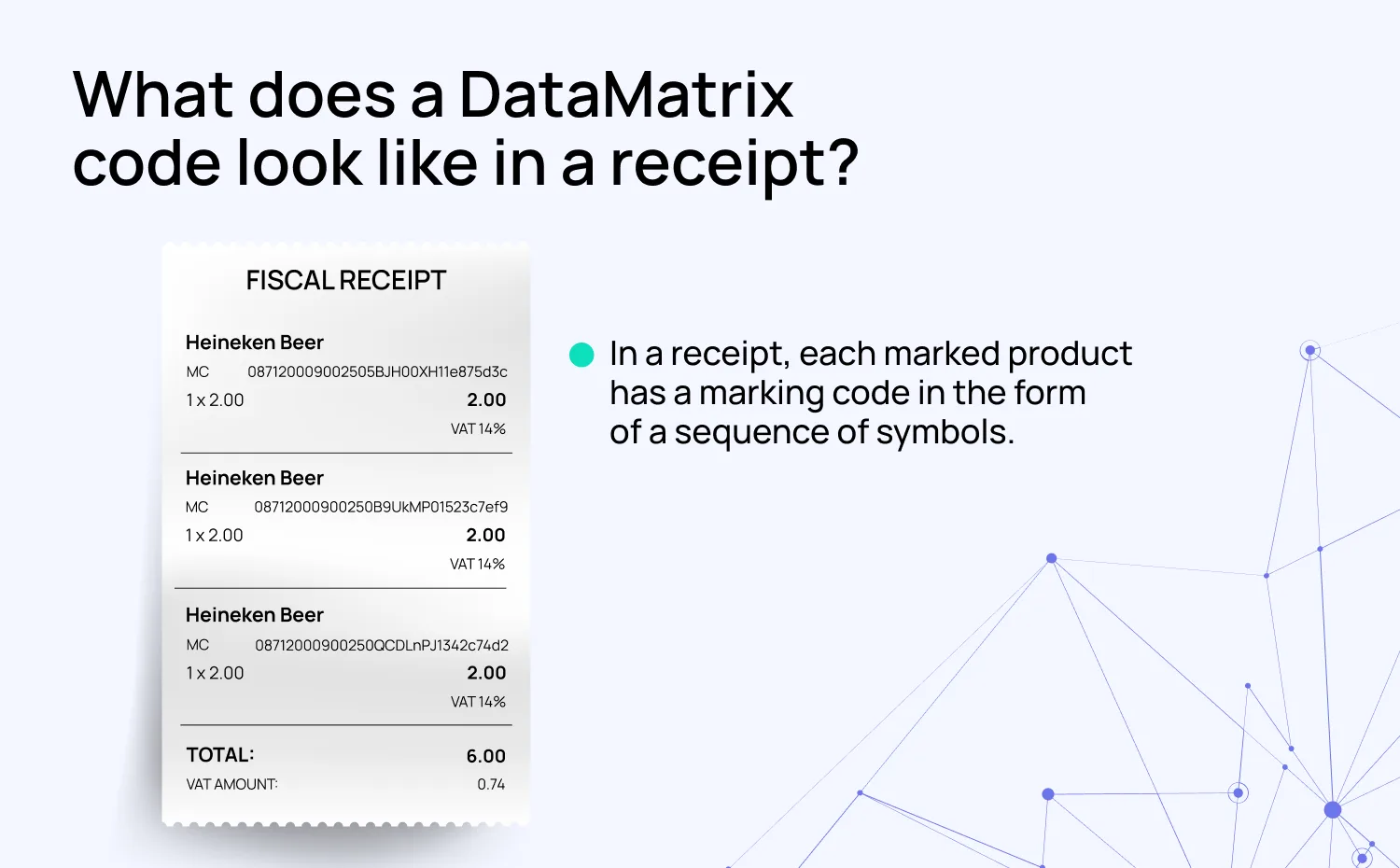

Consumers can also notice DataMatrix codes in regular store receipts that they receive after making purchases.

Why DataMatrix Codes Are Essential for Track and Trace Solutions

In industries such as pharmaceuticals, tobacco, alcohol, electronics, logistics, and even aerospace, maintaining accurate records of every product’s journey is vital.

Track and Trace solutions depend heavily on DataMatrix codes because of the following points:

Compact and High Capacity

DataMatrix codes can store much more information in a small footprint than traditional barcodes, including serial numbers, expiration dates, batch numbers, and even URLs.

Error-Resistant

Its error-correction capabilities ensure that even if part of the code is damaged or obscured, it can still be read accurately.

Fast Scanning

DataMatrix codes can be scanned from any angle, which is particularly helpful in fast-paced environments like warehouses or distribution centers.

Space Efficiency

Given the compact nature of DataMatrix, it’s ideal for marking small items or products where a larger barcode wouldn't fit.

Cost-Effective

DataMatrix is cost-effective to implement because it requires minimal space, simple printing methods, and can be easily integrated into existing systems without significant infrastructure changes.

Compliance Support

DataMatrix codes are implemented according to regulatory standards and anti-counterfeiting measures.

End-to-end Supply Visibility

With DataMatrix codes, it’s possible to easily track and trace each product or part from manufacturing to delivery.

Advanced Security

For enhanced sensitive data protection, DataMatrix codes often include encryption and authentication.

Because of these strengths, DataMatrix codes are the gold standard for industrial traceability, making them indispensable in modern track and trace systems.

If you’re looking for a reliable Track and Trace solution that you could implement in your country, traceCORE Digital Track and Trace for Governments will meet all your needs and beyond.

Visit this page to learn more.

DataMatrix Codes vs. QR Codes: What Is the Difference?

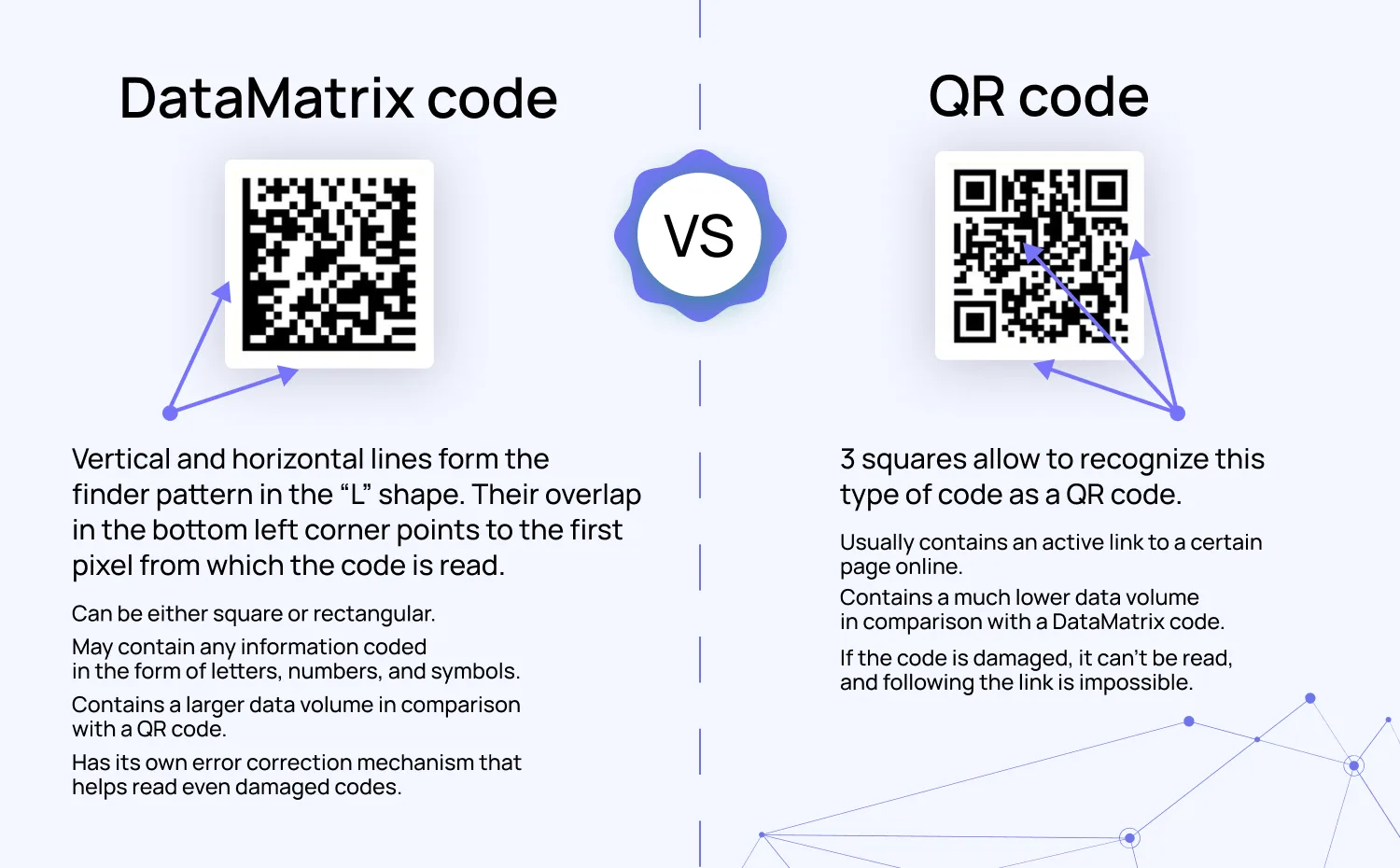

Simple 1D barcodes are very different from DataMatrix codes and QR codes visually, therefore it’s easy to tell them apart.

DataMatrix and QR codes, on the other hand, can often be confused as they look quite similar. However, if you look closely, DataMatrix has the finder pattern located on the left in the "L" shape (in the QR code, there are three corner square symbols).

To learn more about the differences between DataMatrix and a QR code, check out the infographic below.

Enhance Product Supply Chains Using traceCORE Digital Track and Trace

Wondering how you can control the movement of products through the supply chain from manufacturing to the points of sale?

traceCORE Digital Track and Trace for Governments helps:

-

Fight illicit trade

-

Control tax compliance

-

Identify fraud schemes

-

Secure quality and safety of products

-

Support sustainability programs

-

Get real-time data for market and industry analysis

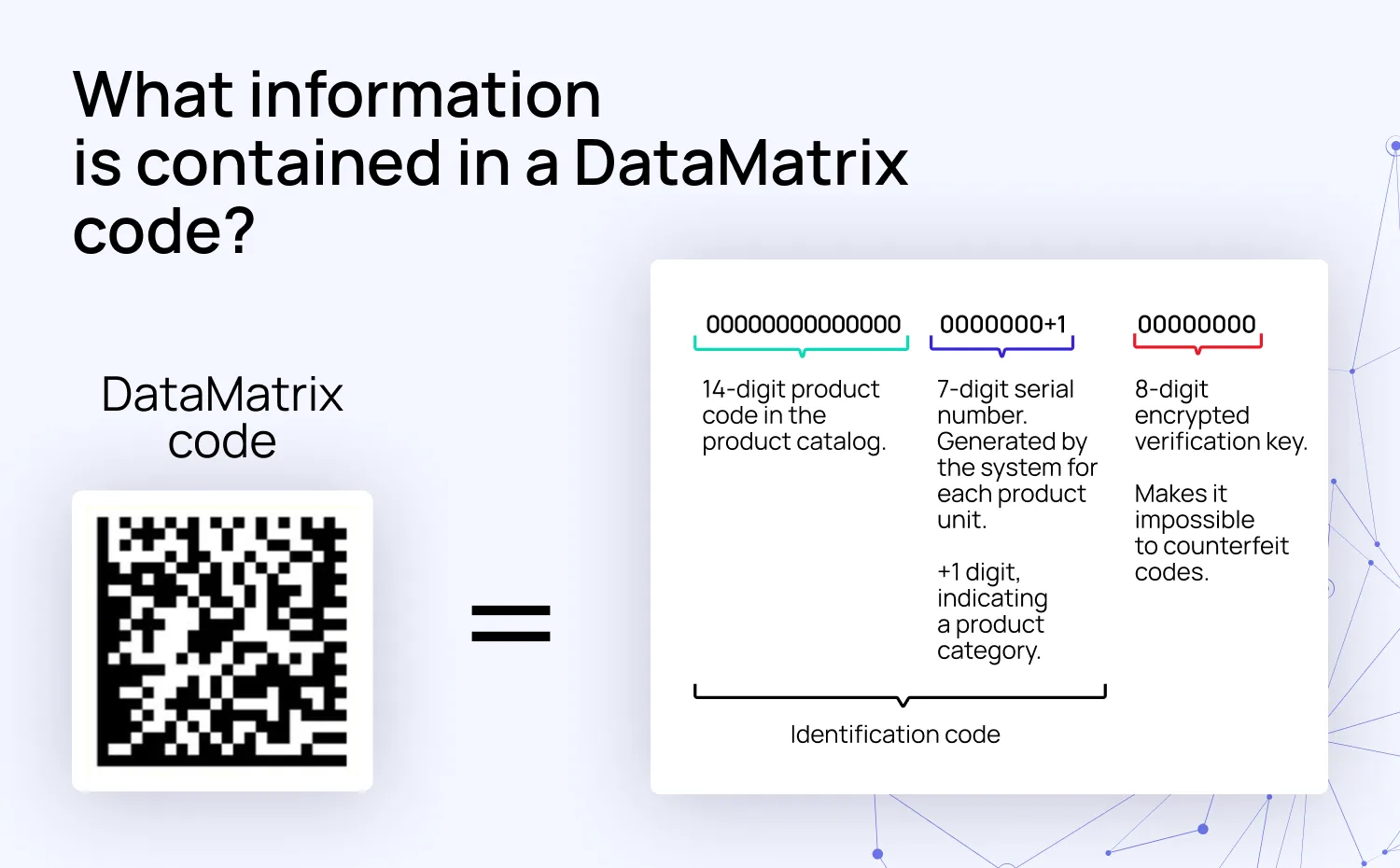

Each product will be assigned a unique digital code by the National Traceability System (also known as a DataMatrix code) and protected with advanced encryption technologies.

DataMatrix codes contain all the necessary information on each product or part to ensure that each unit is identified correctly. Those codes can’t be edited or forged, which enhances the system’s security.

Starting from manufacturing or importing and ending with the purchase by the final consumer, each product movement is reported to the National Traceability System that is fully controlled by a government.

Check out this page to learn more about traceCORE Digital Track and Trace.

If you have any questions about how we can help you enhance your product traceability and supply chain efficiency, don’t hesitate to contact us.

Conclusion

Choosing the right code type depends on application environment. When comparing DataMatrix and QR codes, DataMatrix codes stand out as the best solution for industrial track and trace applications, while QR codes have their place in retail and consumer marketing.

Their ability to encode detailed product information in a tiny space, combined with superior durability and error correction, makes DataMatrix codes ideal for ensuring product safety, regulatory compliance, and supply chain transparency.

If your country needs an efficient Track and Trace system, adopting traceCORE Digital Track and Trace is a reliable, future-proof decision.

.webp)