Track and Trace for Governments

The Impact of AI on Track and Trace Systems

Track and trace technology has become an essential tool in the modern global economy. Once implemented, it enables tracking of individual products from their manufacturers to consumers. Tracking and tracing protects businesses from counterfeiting — the creation of direct copies of their products, theft, smuggling, and even tax evasion. By monitoring products throughout the supply chain, companies can promptly detect issues before they escalate and result in revenue loss.

While some businesses still use traditional traceability methods, many have issues with them due to time-consuming manual processes and higher risks of error. With the rise of artificial intelligence (AI), those methods can be enhanced to revolutionize supply chain management. Implementing modern AI-equipped track and trace software allows governments to use advanced analytics and make faster, more accurate strategic decisions.

6 Reasons Why Governments Should Adopt Digital Track and Trace Technology

When governments implement track and trace systems, they help companies in their countries get up-to-date information on the movement of products and materials across the supply chain from manufacturing or importation to their final destination — points of sale.

Below are six key reasons why governments should adopt this technology.

Supply Chain Resilience

According to McKinsey, the average organization can lose up to 45% of one year’s profits over a 10-year period due to supply chain disruptions.

Track and trace systems would allow businesses to ensure that they are not losing products along the supply chain, while also enabling them to quickly identify and manage risks.

Transparent Processes

When it comes to product movement across the supply chain, it’s important for all parties involved to stay informed.

Track and trace systems can pinpoint the exact location of a product at any stage of its journey, providing reassurance to stakeholders and helping prevent misunderstandings along the way.

Brand Protection

By tackling illicit trade and protecting brands from counterfeiting, governments can develop a positive business environment and investment climate.

Track and trace technology helps businesses secure their supply chains and respond quickly to any disruptions, losses, or violations.

Business Growth

It's difficult for businesses to set growth goals without access to real-time, accurate data.

Digital Track and Trace gives businesses the tools they need to analyze supply chain activity and plan for long-term success.

Audit Optimization

Auditing is essential for transparency and stakeholder trust.

With detailed data from Track and Trace systems, audits can be streamlined, faster, and more accurate.

Environmental Awareness

Track and Trace systems allow businesses to ensure that raw materials and final products comply with environmental regulations — supporting ESG initiatives and reducing carbon footprint.

traceCORE Digital Track and Trace is a system that helps businesses secure their supply chains and empowers governments to enhance excise tax collection, detect fraud, stop illicit networks, protect consumers, and foster fair competition.

The Limitations of Traditional Traceability Systems

According to TGL, there are several key challenges associated with traditional traceability systems:

Limited Visibility and Traceability

Traditional traceability systems often offer limited visibility into product movement across the supply chain.

When information about a product’s origin, journey, or current location is incomplete or outdated, efficient monitoring becomes difficult. This lack of transparency can lead to delays, poor decision-making, and challenges with quality control.

Mistakes and Inaccuracies

Traditional traceability methods often rely on manual processes and paper documentation, which increases the likelihood of mistakes and delays. Manual data entry is prone to human error, while physical documents can be easily lost or damaged.

These outdated systems are also time-consuming and resource-intensive, making automation a significant advantage for improving efficiency and accuracy.

Compliance Challenges

Without automated monitoring, meeting regulatory requirements for traceability and compliance becomes far more difficult.

Traditional systems carry a higher risk of error and often lack the precision needed for accurate reporting. Since regulatory compliance is a critical part of establishing effective traceability, attention to detail and system reliability is essential.

Inefficient Problem Solving

When issues arise — such as shipment delays, product defects, or inventory discrepancies — traditional systems often make it difficult to quickly identify and resolve them.

The lack of real-time data and automated alerts results in slower response times and increased operational risks.

Inadequate Interoperability

When stakeholders across the supply chain use incompatible technologies or data exchange standards, miscommunication and collaboration issues are inevitable.

Ensuring seamless interoperability between all parties is essential to maintaining transparency, avoiding costly errors, and enabling efficient coordination.

Lack of Scalability and Flexibility

Traditional traceability systems often lack the scalability and flexibility needed to respond to shifting market demands.

As businesses grow or adopt new technologies, scaling operations with outdated systems becomes increasingly time-consuming and resource-intensive. Modern, adaptable solutions are essential for supporting long-term growth and innovation.

How AI Can Transform Track and Trace Technology

Businesses are increasingly integrating artificial intelligence (AI) into their supply chains to reduce costs, speed up distribution, and build more resilient strategies against disruptions. By modernizing track and trace systems with AI — and introducing advanced analytics and decision intelligence — organizations can make faster, more informed decisions at strategic, operational, and tactical levels.

AI adoption spans a wide range of industries, from excise goods like tobacco and alcohol to consumer electronics and high-tech sectors.

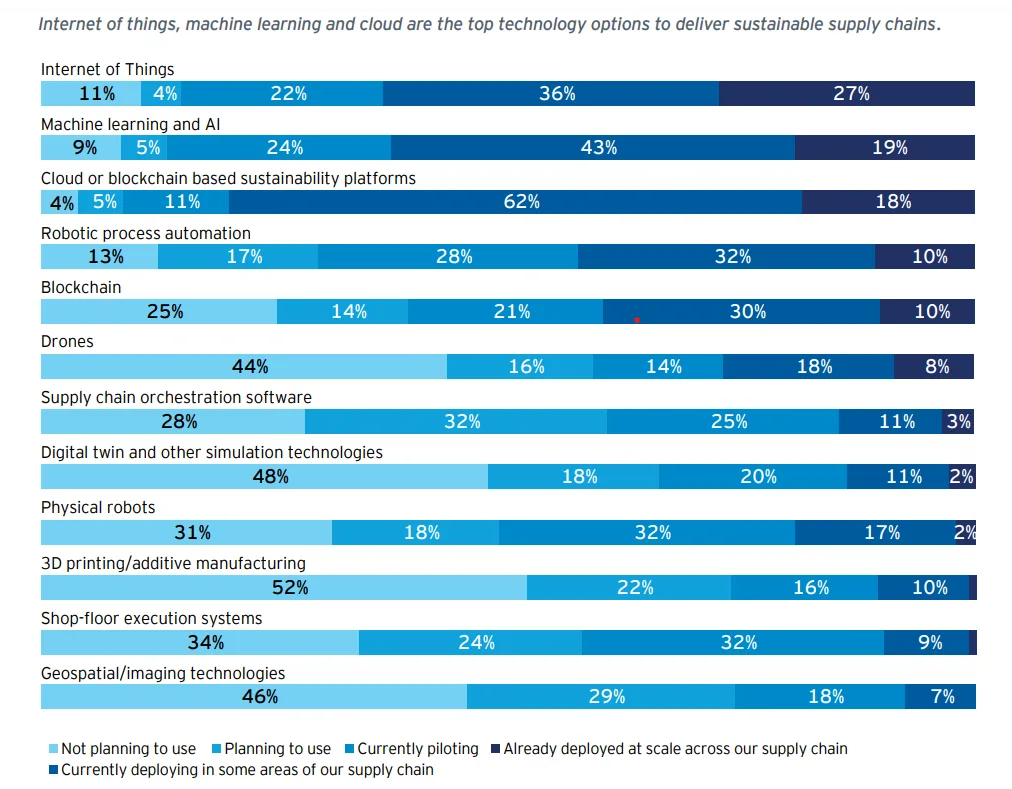

According to a 2022 EY study, 62% of companies are expanding their use of machine learning and other AI tools specifically for sustainability tracking and measurement.

In addition, building a sustainable and autonomous AI-driven supply chain has become a key objective for many companies worldwide.

Source: EY, 2022. "Building supply chain sustainability that can drive revenues and reduce operational risks," https://www.ey.com/content/dam/ey-unified-site/ey-com/en-ca/insights/supply-chain/documents/ey-supply-chain-sustainability-report-2022-007702-22gbl.pdf

Source: EY, 2022. "Building supply chain sustainability that can drive revenues and reduce operational risks," https://www.ey.com/content/dam/ey-unified-site/ey-com/en-ca/insights/supply-chain/documents/ey-supply-chain-sustainability-report-2022-007702-22gbl.pdf

The Role of AI in Track and Trace Technology

Visibility in Real-Time

AI-equipped Track and Trace systems can gather and analyze data from a wide range of sources — including IoT devices, sensors, GPS trackers, and RFID tags.

This real-time data gives businesses full visibility into a product’s location and status at every stage of its journey through the supply chain.

The information can also be used to monitor stock levels and resolve potential issues before they escalate.

Advanced Analytics

By leveraging AI-powered analytics tools, Track and Trace technologies can monitor market trends, operational records, and external factors like economic conditions.

This enables businesses to anticipate delays and supply chain disruptions, allowing for proactive decision-making and reducing the risk of costly downtime.

More Accurate Data

AI-equipped Track and Trace systems also automate key processes such as data entry, record access, and verification. This not only increases speed and efficiency but also significantly reduces the likelihood of human error.

With AI handling the data, businesses benefit from more accurate, reliable, and timely insights.

Improved Decision-Making

Beyond operational improvements, AI-equipped Track and Trace technology can enhance strategic decision-making.

By analyzing large volumes of historical and real-time data, these systems can detect inefficiencies, identify patterns, and recommend optimizations — such as better inventory management, route planning, or production scheduling — all of which contribute to lower costs and improved performance.

Blockchain Systems

Integrating blockchain technology with AI further strengthens the integrity of Track and Trace systems.

Blockchain creates a secure, tamper-proof ledger where every transaction is cryptographically linked to the last, ensuring transparency and accountability across the supply chain.

Better Security and Fraud Prevention

AI-powered Track and Trace systems offer advanced security features.

By analyzing historical tracking data, machine learning models can detect suspicious patterns, anomalies, or irregular behaviors that may signal fraud, theft, or other security threats. This allows businesses to act quickly and protect their assets more effectively.

AI-powered traceCORE Track and Trace for Governments helps control tax payments, combat illicit trade, identify fraud schemes, secure quality and safety of products, support sustainability programs, get real-time data for market and industry analysis, and more.

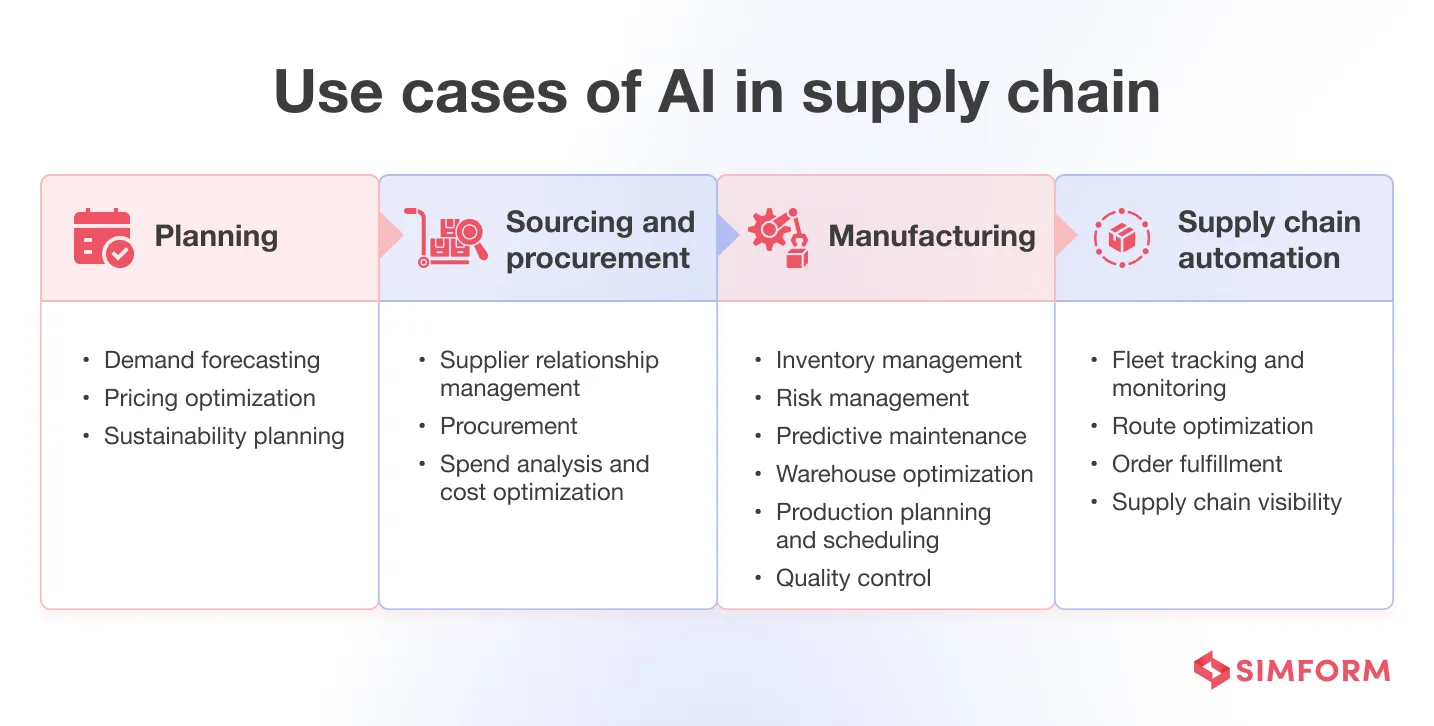

AI in the Supply Chain: Use Cases

To better understand AI's potential, let’s explore key use cases across four stages of product development and movement throughout the supply chain, as outlined by Simform.

Planning

Demand Forecasting

By integrating machine learning into Track and Trace systems, businesses can analyze and process vast amounts of data from multiple sources — including online search trends, social media activity, website traffic, competitor campaigns, purchase history, and even macroeconomic indicators like GDP growth and inflation rates.

This data-driven approach enables more accurate, dynamic demand forecasts, helping companies adapt quickly to changing market conditions.

Pricing Optimization

AI enhances pricing strategies in three key ways:

-

Dynamic Pricing: AI algorithms continuously monitor market trends, competitor pricing, and customer behavior, allowing businesses to adjust prices in real time for maximum competitiveness and profit.

-

Personalized Pricing: Using machine learning, companies can segment customers based on purchasing history, price sensitivity, and demographics. This enables targeted pricing strategies that can increase conversion rates and revenue.

-

Promotional Optimization: AI can simulate and evaluate different promotional strategies to identify the most effective discounts and offers. Advanced algorithms tailor these campaigns to meet specific business objectives and customer needs.

Sustainability Planning

AI supports data-driven decision-making in environmental, social, and governance (ESG) performance. Companies can:

-

Analyze energy usage patterns and reduce consumption

-

Minimize overproduction and eliminate material waste

-

Ensure eco-friendly product design and development

-

Collaborate with suppliers to strengthen sustainability initiatives

By tracking and optimizing these elements, AI helps businesses build greener, more responsible supply chains.

Source: KPMG, 2024. "Unchain the supply chain. How to break free from supply chain disruptions using integrated AI planning," https://kpmg.com/kpmg-us/content/dam/kpmg/pdf/2024/018035-1a-unchain-the-supply-chain.pdf

Sourcing and Procurement

Supplier Relationship Management

AI-enhanced supplier relationship management systems use machine learning, natural language processing (NLP), and advanced data analytics to help businesses identify, evaluate, and manage their supplier base more effectively.

For example:

-

Machine learning models analyze large datasets to identify the most suitable suppliers based on performance, reliability, and compliance history.

-

NLP algorithms can scan supplier contracts to detect risks or non-compliance with regulatory requirements — a task that would be time-consuming and error-prone if done manually.

Procurement

AI is transforming procurement by automating and streamlining key processes such as:

-

Identifying global supply trends across commodities and products

-

Extracting and organizing relevant data from invoices and contracts

-

Monitoring compliance automatically

-

Managing the full contract lifecycle with minimal manual input

These capabilities accelerate procurement workflows while improving accuracy and strategic planning.

Spend Analysis and Cost Optimization

AI-powered spend analysis tools can process and categorize vast amounts of purchasing data, regardless of how different vendors or departments format it. This unified view helps organizations:

-

Identify cost-saving opportunities through vendor consolidation

-

Detect irregular spending patterns

-

Negotiate more favorable contracts based on spend trends

For cost optimization, AI models assess historical pricing, market dynamics, and supplier performance to:

-

Forecast future price changes

-

Recommend the optimal timing for purchases

-

Automate routine procurement tasks to boost efficiency and reduce human error

Manufacturing

Inventory Management

AI-driven inventory management uses real-time data and predictive analytics to improve forecasting and inventory planning. Businesses can:

-

Generate more accurate sales forecasts

-

Set optimal reorder points and safety stock levels

-

Avoid stockouts and overstocking

Additionally, clustering algorithms and machine learning models can segment customers based on purchasing behavior, preferences, and demographics. This enables companies to align inventory strategies with the needs of specific customer groups, improving efficiency and service levels.

Supply Chain Risk Management

AI enhances risk management by helping businesses predict, prevent, and respond to potential disruptions in the supply chain. By analyzing vast and varied datasets, AI can:

-

Forecast risks such as material shortages, geopolitical events, or logistical delays

-

Provide real-time visibility into product movement

-

Enable proactive decision-making to mitigate disruption

Predictive Maintenance

AI-powered predictive maintenance allows companies to maximize equipment uptime and extend asset life. Key applications include:

-

Failure prediction: Anticipating equipment issues before they occur

-

Prescriptive maintenance: Recommending actions to improve performance

-

Asset optimization: Extending the life of critical infrastructure

This helps reduce unplanned downtime and maintenance costs.

Warehouse Automation

AI is revolutionizing warehouse operations through technologies such as:

-

Autonomous Mobile Robots (AMRs) for internal transport

-

Computer vision for automated item picking and packing

-

Natural language processing (NLP) for intelligent warehouse management systems and chatbots

-

Image and language generation models for improved documentation and customer interaction

These innovations streamline operations, boost accuracy, and reduce manual labor.

Production Planning and Scheduling

AI enables dynamic, real-time production planning. Businesses can:

-

Adjust schedules based on demand shifts or resource availability

-

Allocate labor and materials more efficiently

-

Integrate AI with IoT and automation systems to boost agility and throughput

This results in reduced costs and on-time delivery performance.

Quality Control

AI-powered machine vision systems improve quality inspections by analyzing large datasets of both defective and flawless product samples. Benefits include:

-

Detecting defects with higher accuracy than manual inspections

-

Identifying complex patterns or anomalies that humans may miss

-

Reducing reliance on human inspectors while maintaining high quality standards

These systems continuously learn and adapt, helping to enhance overall product quality.

Source: Lihui Wang, KTH Royal Institute of Technology, 2019. "From Intelligence Science to Intelligent Manufacturing," https://www.researchgate.net/publication/333567029_From_Intelligence_Science_to_Intelligent_Manufacturing

Source: Lihui Wang, KTH Royal Institute of Technology, 2019. "From Intelligence Science to Intelligent Manufacturing," https://www.researchgate.net/publication/333567029_From_Intelligence_Science_to_Intelligent_Manufacturing

Supply Chain Automation

Fleet Tracking and Monitoring

AI-powered telematics systems offer real-time insights into vehicle location, speed, fuel consumption, and mechanical health. More than just tracking, these systems also:

-

Analyze driver behavior to detect risky actions like speeding or harsh braking

-

Provide personalized coaching or training programs based on driver performance data

-

Help reduce accidents, lower insurance costs, and improve fuel efficiency

Route Optimization

AI enhances logistics through real-time traffic analysis by leveraging data from GPS, traffic cameras, and mobile apps. These systems:

-

Recommend alternate routes to avoid congestion

-

Reduce fuel consumption and delivery times

-

Use machine learning to identify and predict problematic routes or bottlenecks

-

Tailor routing strategies to specific business goals or delivery constraints

The result: faster, more reliable deliveries and improved customer satisfaction.

Order Fulfillment

AI tools support efficient and accurate order fulfillment by analyzing real-time data on:

-

Inventory levels

-

Sales patterns

-

Customer demand

With this data, businesses can predict future needs and automate key processes such as picking, packing, and shipping — leading to faster order turnaround and reduced manual errors.

Supply Chain Visibility

AI, including large language models (LLMs), enables end-to-end visibility across the supply chain. These tools can:

-

Analyze data from customs declarations, freight bookings, and product orders

-

Track changes in consumer demand via POS data, social media, and customer reviews

-

Simulate various operational scenarios and recommend improvements

This kind of visibility allows for smarter decision-making and early detection of disruptions — critical for maintaining smooth operations in complex supply networks.

Source: McKinsey & Company, 2021. "Succeeding in the AI supply-chain revolution," https://www.mckinsey.com/industries/metals-and-mining/our-insights/succeeding-in-the-ai-supply-chain-revolution

Conclusion

AI-powered Track and Trace technology offers a competitive edge by improving operational efficiency, boosting decision-making capabilities, enhancing security, and delivering predictive insights. These capabilities benefit a wide range of industries — from logistics and manufacturing to healthcare, retail, and public safety.

Solutions like traceCORE Track and Trace for Governments are built to be both flexible and scalable, empowering public authorities to protect sensitive product categories, combat illicit trade, and ensure regulatory compliance in dynamic markets.

.webp)